Description

Mills Machine custom manufactured stabilizers are used to keep the drill rod centered in the hole. They are available in a wide range of construction with all wear surfaces coated with carbide hard facing.

All stabilizers are made with a heavy-walled steel pipe. Stabilizers larger than 8 1/2 OD are normally made with an inner as well as an outer pipe for rigidity and strength. There is full, direct flow circulation provided. We will discuss the specific design with you before accepting your order.

All stabilizers are made with 4142 heat-treated, steel tool joints. All ribs are fully welded on both sides and have hard facing. Optional replaceable cast carbide ribs are available to increase the gage life.

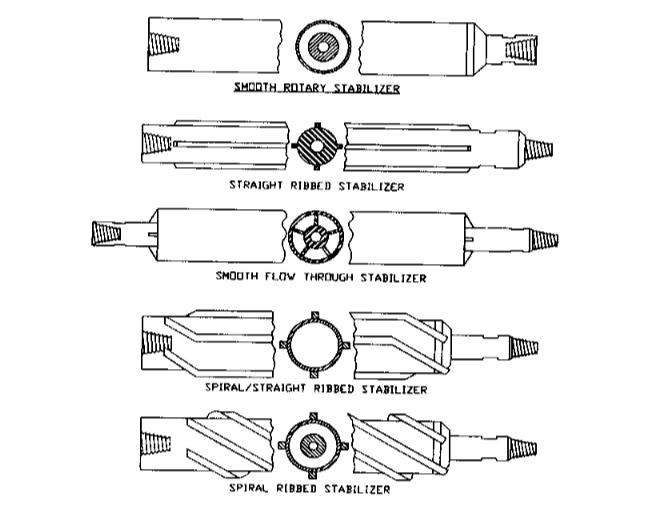

Mills offers five standard styles of stabilizers.

The first type is the Smooth Stabilizer that is normally a couple of inches smaller than the borehole ID and can have an inner and outer barrel.

The Flow Through is another variation for larger diameters that allow the cuttings to flow between the inner and outer barrel.

Straight Ribbed Stabilizers can have three or more ribs (4 ribs is the most common) depending on the application. The ribs are welded to the steel tubing and are hard-faced down the entire length to extend the gage life.

A variation on the straight rib design is the Spiral Ribbed stabilizer. The hard-faced ribs are hand spiraled around the steel body to give 360-degree wall contact and assist in cutting removal.

The combination Spiral-Straight Ribbed stabilizer shown below gives the wall contact of the spiral stabilizer while reducing the cost of the spiraling process.

Finally, there is the Overhammer Stabilizer. The Mills Machine over-hammer stabilizer is built with the rugged construction that is standard for our units and with the ability to take the punishment of direct connection to the downhole hammer. The stabilizer is designed for the specific hammer that it is coupled with.